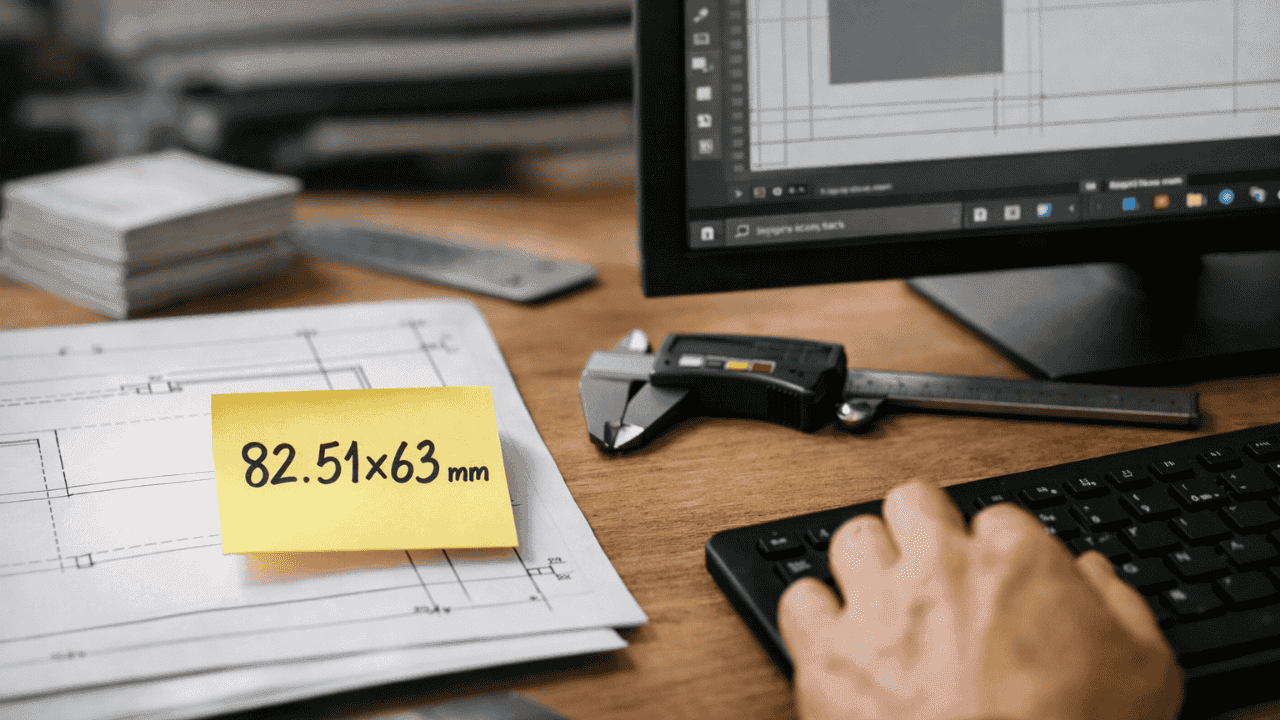

82.51×63 doesn’t leave room for laziness. It sits in that uncomfortable middle ground where assumptions break things and shortcuts show up fast. When this size appears in a workflow, it demands intent. You can’t eyeball it. You can’t round it without consequences. And you definitely can’t treat it like a placeholder. People who work with 82.51×63 learn quickly that precision isn’t a preference—it’s the cost of entry.

That’s why this dimension keeps surfacing in design, print, and production conversations. Not because it’s trendy, but because it exposes who’s paying attention.

Why 82.51×63 Shows Up in Professional Workflows

The presence of 82.51×63 usually signals a constraint-driven job. It’s rarely chosen for aesthetics alone. It appears when something has to fit, align, pass through a system, or comply with an existing physical or digital boundary.

In print environments, 82.51×63 often sits close to standardized card or insert sizes, but just far enough away to cause trouble if handled casually. That extra fraction forces recalculation. Trim lines need adjustment. Bleeds need to be deliberate. Nothing defaults cleanly.

In manufacturing or packaging, 82.51×63 tends to exist because of upstream limitations. A mold, a slot, a carrier, or a shipping format dictated it. Downstream teams don’t get to debate it; they have to work with it. That’s where mistakes surface. A rounded-down file here, a misread unit there, and suddenly nothing fits.

Digital teams encounter 82.51×63 in a different way. It becomes a conversion problem. DPI, scaling, and screen rendering all step in. Anyone who treats it as “close enough” ends up with artifacts, soft edges, or alignment drift that wasn’t there in the original file.

Precision Beats Convenience Every Time

82.51×63 punishes convenience. Rounding it to 83×63 or 82.5×63 feels harmless until it isn’t. That half millimeter creeps into margins, throws off spacing, or creates friction during assembly.

The professionals who handle 82.51×63 well share one trait: they respect decimals. They don’t see them as noise. They see them as instructions.

This is especially visible in print production. Plates, cutters, and finishing equipment don’t care about your intent. They execute numbers. If the file says 82.51×63, the machine assumes you meant it. If you didn’t, that’s your problem, not the machine’s.

The same logic applies in digital exports. Convert 82.51×63 at 300 DPI, and you’re locked into pixel values that don’t land on clean integers. Designers who understand this plan for it. Designers who don’t end up nudging layers by hand and wondering why nothing aligns.

The Hidden Cost of Treating 82.51×63 as “Close Enough”

The most common failure around 82.51×63 isn’t misunderstanding. It’s dismissal. Someone decides it’s basically another size they’ve handled before and moves on.

That decision has a cost.

In print, it shows up as white edges where bleed was trimmed incorrectly. In packaging, it shows up as inserts that bow or jam. In digital, it shows up as exports that look fine on one screen and off on another.

None of these failures are dramatic on their own. That’s why they keep happening. But stacked across a run, a campaign, or a product line, they add up. Reprints. Delays. Quiet frustration between teams who assume the other side messed up.

82.51×63 isn’t unforgiving. It’s honest. It gives you exactly what you ask for.

Where 82.51×63 Fits—and Where It Doesn’t

Not every project deserves this level of specificity. That’s an important distinction. 82.51×63 belongs in environments where fit and consistency matter more than speed.

It works well for controlled outputs: printed cards, fixed-format inserts, labels that must align with hardware, or any component that interfaces with another system. In these cases, 82.51×63 becomes part of a chain. Break one link and the rest suffer.

It’s a poor choice for flexible layouts or responsive digital designs. Trying to force 82.51×63 into fluid contexts usually creates friction. The size resists scaling because it was never meant to stretch. When teams fight that, they lose time.

Knowing when not to use 82.51×63 is just as important as knowing how to use it.

Conversion Errors Are the Silent Killer

Ask ten people to convert 82.51×63 into pixels and you’ll get ten different answers. Not because the math is hard, but because the assumptions differ.

DPI changes everything. So does the direction of conversion. Are you scaling up for print or down for screen? Are you maintaining physical size or visual proportion? These decisions matter, and 82.51×63 exposes sloppy thinking fast.

The worst errors come from automatic tools. They promise accuracy, but they don’t understand context. They’ll happily spit out a pixel dimension without telling you that rounding occurred or that the result won’t align cleanly with your grid.

Experienced designers check the math themselves. They test outputs. They don’t trust defaults. That’s not paranoia—that’s survival when dealing with sizes like 82.51×63.

Why Teams Argue About 82.51×63 More Than They Should

Conflict around 82.51×63 rarely comes from the number itself. It comes from ownership. Who decided this size? Who’s responsible for maintaining it? Who signs off when compromises are suggested?

Designers may see 82.51×63 as restrictive. Engineers may see it as non-negotiable. Production teams may see it as risky if files aren’t perfect. Each perspective is valid, but only one version of the size can exist.

The healthiest teams document decisions around 82.51×63 early. They lock units. They specify tolerances. They agree on what can and can’t change. That clarity removes friction later.

When those conversations don’t happen, the size becomes a scapegoat. It shouldn’t be.

The Decimal Is Doing More Work Than You Think

That .51 isn’t decorative. It’s usually there because something upstream demanded it. Maybe it’s the result of a conversion from another unit. Maybe it compensates for material behavior. Maybe it aligns with an existing standard that isn’t obvious at first glance.

Stripping it away breaks intent.

Professionals who respect 82.51×63 treat it as a complete instruction, not a suggestion. They ask why it exists, but they don’t ignore it while waiting for an answer.

When 82.51×63 Becomes a Quality Filter

There’s an unspoken truth in production environments: sizes like 82.51×63 separate careful operators from careless ones. Anyone can handle round numbers. Fractions expose habits.

Teams that consistently deliver clean results with 82.51×63 tend to have strong process discipline. Version control matters. File naming matters. Proofing matters. Nothing slips through “just this once.”

That discipline carries over into other work. The size itself isn’t special. The mindset it demands is.

Final Take

82.51×63 isn’t difficult. It’s demanding. It forces decisions, exposes assumptions, and rewards people who slow down just enough to get it right. Treat it casually and it will cost you. Treat it with respect and it becomes invisible—doing its job without drama. That’s the real test of professional work.

FAQs

- Why does 82.51×63 cause so many production issues?

Because people assume it behaves like a rounded size and skip precision steps that it actually requires. - Is 82.51×63 better suited for print or digital work?

It performs best in controlled print or fixed-format outputs where scaling isn’t expected. - Should 82.51×63 ever be rounded for convenience?

Only if every downstream stakeholder agrees and the impact is understood in advance. - What’s the most common mistake when handling 82.51×63 files?

Automatic conversions without checking how decimals were handled. - How can teams reduce friction around 82.51×63?

By locking units early, documenting tolerances, and treating the size as intentional rather than accidental.