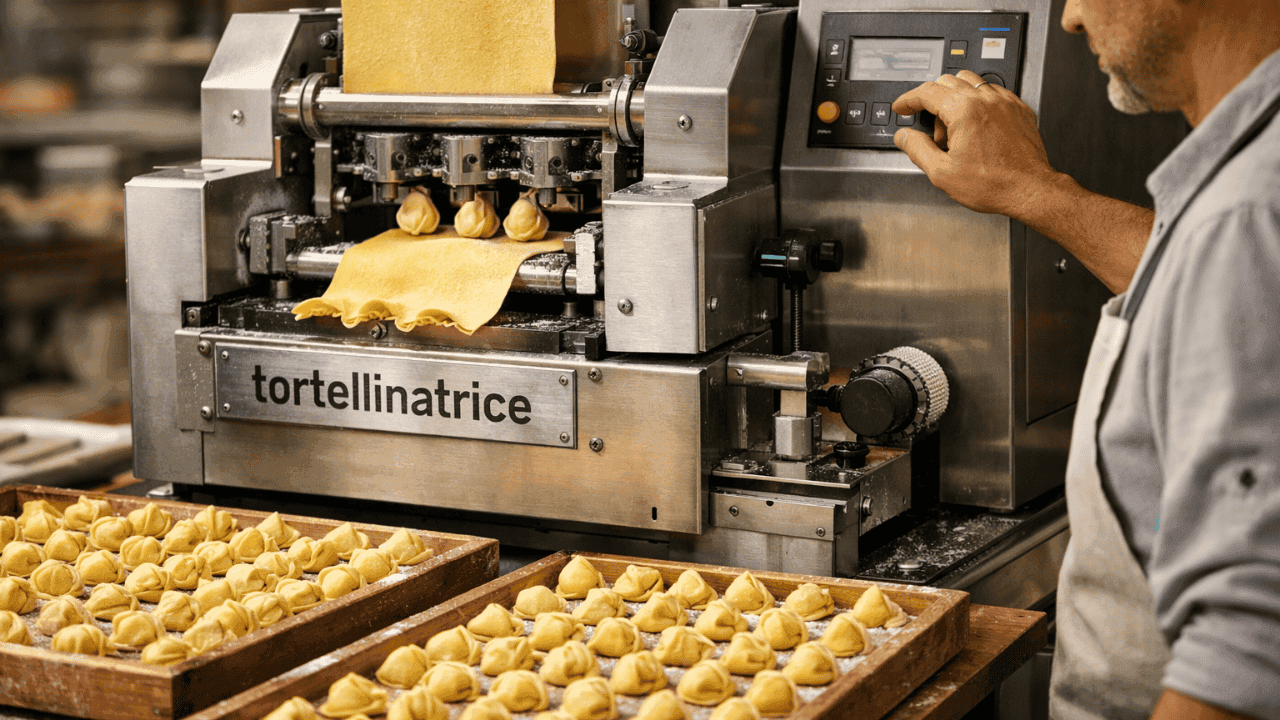

Anyone who has folded tortellini by hand for hours knows the romance fades fast. Precision matters. Speed matters even more. A kitchen that relies on memory and muscle alone eventually hits a wall. That’s where a tortellinatrice earns its place. Not as a gimmick, not as a shortcut, but as a pressure test for how serious a producer really is about consistency, volume, and control.

The tortellinatrice doesn’t rescue bad dough or sloppy filling. It exposes them. When everything upstream is done right, the machine rewards discipline with output that no human team can sustain day after day.

Why Production Breaks Without the Right Machine

Handmade tortellini look charming in small batches. Try serving a full dining room or supplying retail orders and the cracks show fast. Uneven seals lead to blowouts. Inconsistent size wrecks cooking times. Labor costs spiral. Staff burn out.

A tortellinatrice fixes none of this automatically. What it does is remove human variability from folding and closing, which is the most failure-prone stage of tortellini production. Once that variable is gone, problems become easier to identify and fix. Dough hydration. Filling texture. Sheet thickness. Everything becomes measurable instead of guesswork.

That’s why high-end pasta shops adopt a tortellinatrice early, not late. Waiting too long locks bad habits into the workflow.

How a Tortellinatrice Actually Fits Into a Real Kitchen

The fantasy version shows a machine quietly producing perfect tortellini while the kitchen relaxes. Reality is more demanding.

A tortellinatrice becomes the center of the pasta line. Dough prep has to match the feed speed. Filling must be mixed to exact resistance or the forming heads choke. Cleaning cycles must be planned or production stalls.

In exchange, output becomes predictable. A restaurant that once capped tortellini service can now commit to it nightly. A small producer can take wholesale orders without gambling on overtime. That reliability is the real value.

Manual, Semi-Automatic, and Fully Automatic Models: The Real Differences

The market splits cleanly into three categories, and pretending otherwise leads to bad purchases.

Manual and semi-automatic machines suit kitchens that want help with forming but still rely heavily on hand feeding. They demand attention and skill, but cost less and take less space. For restaurants producing tortellini as a signature dish rather than a bulk product, this setup often makes sense.

Fully automatic systems are built for volume. Continuous dough feed, timed filling extrusion, synchronized cutting. These machines punish inconsistency but reward preparation. Once dialed in, a tortellinatrice at this level can run for hours with minimal intervention.

Multi-format machines sit in between. Swapping dies to move from tortellini to cappelletti or tortelloni sounds appealing. In practice, changeovers take time and discipline. They work best in shops that plan production days carefully instead of chasing daily variety.

Speed Isn’t the Metric That Matters Most

Manufacturers love quoting output numbers. Pieces per hour. Kilograms per shift. Those figures matter, but they’re not decisive.

What separates a good tortellinatrice from a frustrating one is control. Can you fine-tune fold tension without tools? Does the filling deposit stay centered at higher speeds? Can the machine handle slight dough temperature swings without tearing?

Machines that chase raw speed often sacrifice tolerance. For kitchens without industrial climate control, that tradeoff hurts more than it helps.

Consistency Changes How Recipes Are Written

Once a tortellinatrice enters the process, recipes evolve. Fillings get smoother. Particle size shrinks. Fat ratios adjust. Dough formulas tighten.

This isn’t compromise. It’s refinement. The machine forces clarity. Either a filling holds its shape under pressure or it doesn’t. Either a dough seals cleanly or it fails every tenth piece.

Chefs who resist this adjustment usually blame the machine. Chefs who adapt end up with better tortellini than before.

Maintenance Is Not Optional, and It’s Not Complicated

A tortellinatrice doesn’t tolerate neglect. Flour dust builds fast. Filling residue turns rancid faster. Bearings wear silently.

The upside is that most machines are mechanically simple. Stainless steel surfaces, removable forming heads, accessible rollers. Daily cleaning prevents almost every long-term issue. Weekly inspection catches the rest.

What kills machines isn’t complexity. It’s rushing shutdown procedures and skipping teardown because “we’ll do it tomorrow.”

Labor Costs Shift, Not Disappear

There’s a myth that a tortellinatrice replaces people. It doesn’t. It reallocates them.

Less time goes into folding. More time goes into prep, monitoring, and quality checks. Skilled hands move upstream. The work becomes cleaner, less repetitive, and easier to train.

For businesses struggling to retain staff, this shift matters. Repetitive hand folding burns people out. Running a tortellinatrice keeps them engaged and accountable.

Quality Control Becomes Visible Instead of Emotional

Without a machine, quality debates turn personal. One cook’s tortellini look different from another’s. Arguments get subjective fast.

A tortellinatrice removes that ambiguity. If pieces fail, they fail consistently. That makes fixes obvious. Adjust the sheet thickness. Change filling density. Modify closure pressure.

The machine doesn’t care about ego. It responds to physics. Kitchens that embrace that mindset improve faster.

When a Tortellinatrice Is the Wrong Choice

Not every operation needs one. Tiny menus. Seasonal pop-ups. Educational kitchens focused on hand technique. In these cases, the machine adds complexity without payoff.

The red flag is inconsistency in demand. If tortellini are an occasional special, a tortellinatrice sits idle too often to justify its footprint. Machines thrive on repetition.

Buying one to chase an idea rather than support an existing workflow is how budgets get burned.

The Italian Tradition Argument Misses the Point

Purists argue that machines dilute tradition. That argument collapses under scrutiny.

Italian pasta culture has always adapted tools to scale. What matters is shape, seal, texture, and filling balance. A tortellinatrice doesn’t erase those standards. It enforces them.

The worst tortellini on the market are not machine-made. They’re rushed, underfilled, poorly sealed pieces made by hand under pressure.

Choosing the Right Machine Is About Honesty

The best tortellinatrice is the one that matches how you actually work, not how you imagine working.

If your dough changes daily, avoid ultra-sensitive systems. If you lack space, don’t buy for future volume that may never come. If you hate maintenance, no machine will save you.

The kitchens that succeed with a tortellinatrice are brutally honest about their habits. The ones that fail blame the equipment.

Final Takeaway

A tortellinatrice doesn’t elevate a kitchen by default. It exposes it. Discipline in, consistency out. Chaos in, chaos multiplied. Used well, it turns tortellini from a fragile specialty into a reliable cornerstone. Used poorly, it becomes an expensive mirror showing exactly what’s broken upstream. The machine isn’t the leap. The mindset is.

FAQs

How long does it usually take to dial in a tortellinatrice for a new filling?

Expect several test runs. Most kitchens need half a day to adjust texture, pressure, and timing before production stabilizes.

Can a tortellinatrice handle traditional meat fillings without clogging?

Yes, but only if the grind is fine and fat distribution is controlled. Chunky mixes cause most jams.

Is noise a real issue with these machines in small kitchens?

Mid-range models are manageable. Large automatic systems can dominate the room and require layout planning.

Does switching pasta formats frequently increase wear?

Frequent die changes don’t damage the machine, but rushed reassembly causes alignment problems that show up later.

What’s the biggest mistake first-time buyers make?

Buying for maximum output instead of daily reality. Oversized machines magnify workflow problems instead of fixing them.