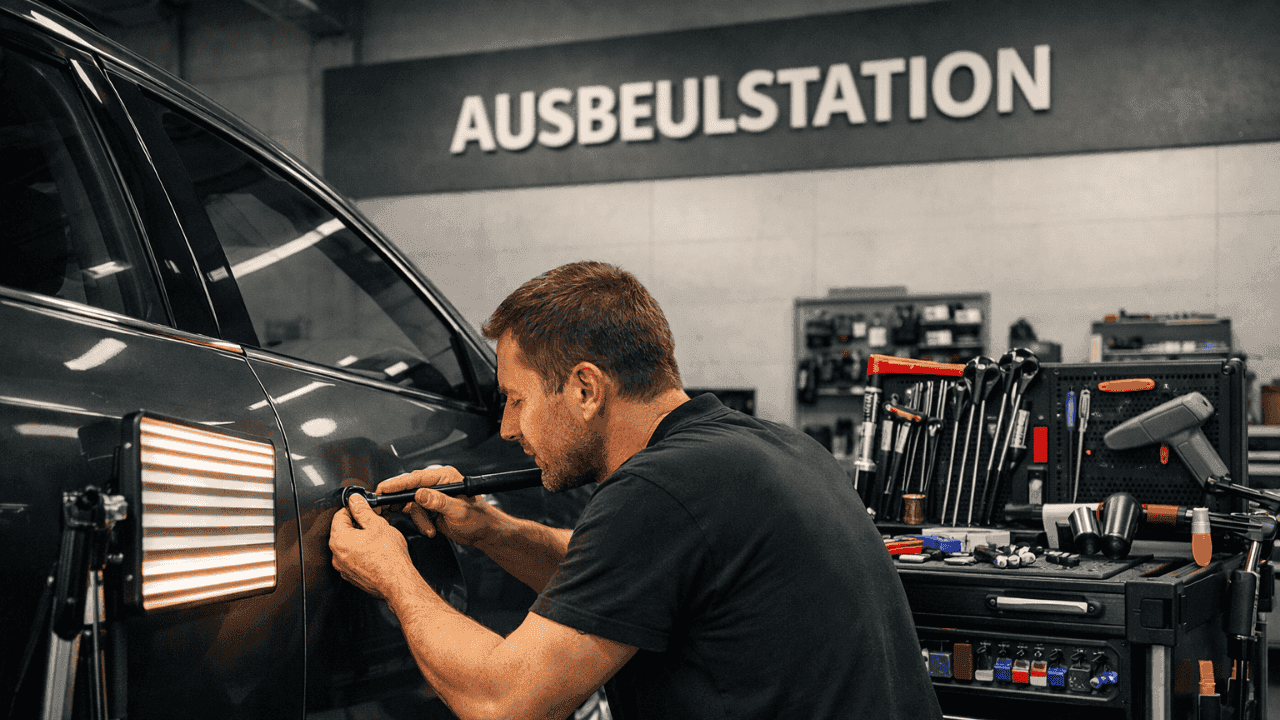

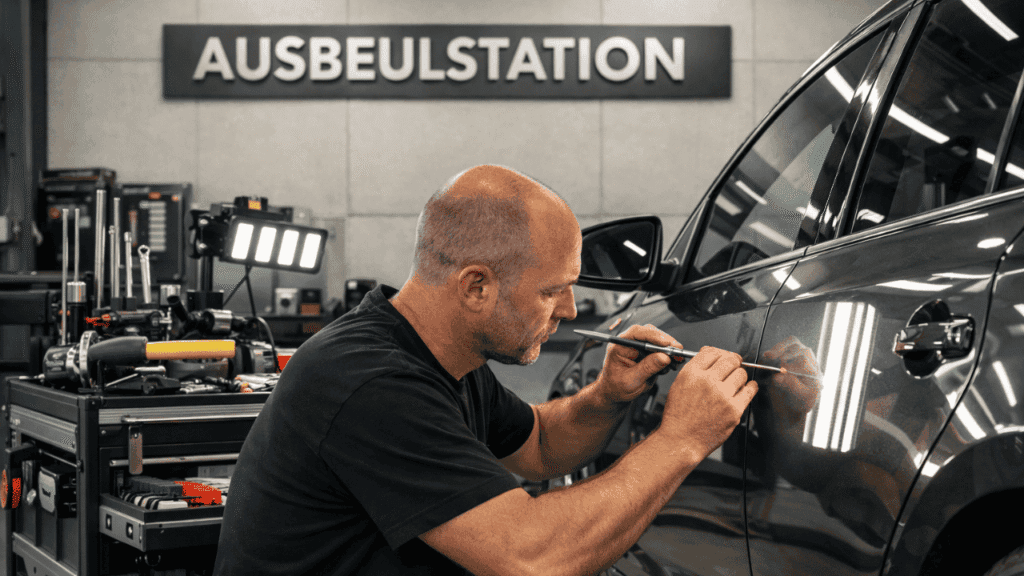

Body repair is full of shortcuts, and most of them leave scars. Anyone who’s watched filler crack after two winters or seen mismatched paint under workshop lights knows the damage isn’t always obvious on day one. A well-run ausbeulstation takes a harder line. It focuses on restoring metal instead of hiding mistakes, and that single decision changes everything about the repair outcome.

This isn’t about nostalgia for old-school craftsmanship. It’s about precision, speed, and resale value. Workshops that rely on an ausbeulstation aren’t chasing volume with cheap fixes. They’re building a process that respects the car and the customer.

Why an Ausbeulstation Changes Repair Decisions Inside a Workshop

The presence of an ausbeulstation forces discipline. When a shop has the tools, lighting, and layout to reshape panels correctly, technicians stop reaching for filler as a reflex. They assess damage differently. Shallow dents, door dings, hail marks, and even light crease damage get treated as metal problems, not paint problems.

That shift matters. Repairs routed through an ausbeulstation usually keep factory paint intact. That alone removes repaint risks like color mismatch, overspray, or long-term peeling. It also shortens repair cycles. No drying time. No paint booth scheduling. No waiting on material deliveries.

From a business standpoint, the ausbeulstation becomes a profit center instead of a bottleneck. Jobs move faster, insurance claims close sooner, and bays free up without sacrificing quality.

The Physical Setup That Separates Serious Stations From Improvised Ones

Not all ausbeulstation setups deserve the name. The difference shows up in lighting, access, and tool control.

Proper reflection lighting is non-negotiable. Without controlled light lines, technicians are guessing. A serious ausbeulstation uses adjustable LED panels or boards that reveal surface distortion immediately. Every high spot, every low ripple, visible in real time.

Tool access matters just as much. PDR rods, hooks, knockdowns, glue pullers, and spotters need to be within reach, organized by use, not dumped into drawers. Time wasted hunting tools breaks concentration, and concentration is everything when reshaping metal.

Mobility also plays a role. Many modern ausbeulstation designs sit on rolling frames so the setup comes to the car, not the other way around. That reduces repositioning and keeps repairs consistent across bays.

Metal-First Repairs Preserve Value in Ways Paint Never Can

Repainted panels are easy to spot for anyone who knows where to look. Paint thickness gauges don’t lie. Even perfect color matches can show irregular clear coat depth or altered texture. Once a panel is painted, the car’s history changes.

An ausbeulstation avoids that outcome whenever possible. By working the metal back to shape, the original paint stays untouched. For leased vehicles, resale-focused owners, and high-end cars, this approach isn’t optional. It’s expected.

Insurance companies know this too. Many now favor repairs completed through an ausbeulstation when damage qualifies. It lowers claim costs and reduces post-repair complaints. Shops that can document metal restoration instead of filler-heavy work gain trust faster.

Glue Pulling and Spot Techniques Are Not Equal Solutions

There’s a tendency to lump all dent repair methods together. That’s lazy thinking. Within an ausbeulstation, glue pulling and spot-based methods serve different purposes, and misusing either creates problems.

Glue pulling works best on shallow dents where backside access is blocked. Roof rails, double-layer panels, and reinforced doors often fall into this category. When done correctly, the metal rises evenly without stressing paint.

Spot weld pulling belongs to controlled structural correction. It’s not a blunt instrument. In a disciplined ausbeulstation, spot pullers are used sparingly, followed by careful planishing to restore contour. Shops that skip this finesse end up with stretched metal and surface waves.

The skill lies in choosing the method, not owning the tool.

Training Matters More Than Equipment Lists

Anyone can buy ausbeulstation equipment. Few invest properly in technician training. That gap shows immediately in finished work.

Metal memory, tension points, and panel behavior differ across manufacturers. Aluminum reacts nothing like steel. High-strength steels punish overcorrection. An ausbeulstation only performs as well as the person reading those signals.

Experienced technicians develop rhythm. They know when to stop pushing, when to tap down, and when to change angles. That judgment doesn’t come from manuals. It comes from repetition and mentoring. Shops that treat ausbeulstation training as optional end up blaming tools for human mistakes.

Where an Ausbeulstation Makes the Most Sense

Not every dent belongs there. Deep tears, cracked paint, and structural misalignment still require conventional body work. The value of an ausbeulstation is knowing its limits and exploiting its strengths.

Hail damage is the obvious candidate. Hundreds of small dents across horizontal panels can be corrected faster and cleaner through a dedicated ausbeulstation than through repainting half a car.

Parking damage comes next. Door dings, shopping cart hits, and minor bumper edge dents are perfect fits. Fleet operators and dealerships rely on ausbeulstation workflows to keep vehicles presentable without inflating costs.

Electric vehicles add another layer. Battery placement and high-voltage systems restrict panel access. Glue-based ausbeulstation techniques often become the safest option when interior disassembly isn’t practical.

Workflow Discipline Reduces Comebacks

Comebacks kill margins. An ausbeulstation reduces them by enforcing step-by-step inspection during the repair itself. Reflection lights catch imperfections before the car leaves the bay. There’s no hiding behind glossy clear coat.

Good stations also document work. Before-and-after photos, paint thickness readings, and repair notes protect both shop and customer. Transparency builds confidence, and confidence brings repeat business.

Rushed repairs skip these steps. Shops that treat the ausbeulstation as a side service instead of a core process feel that pain later.

Mobile Ausbeulstation Systems Are Changing Shop Layouts

Space is expensive. Mobile ausbeulstation systems answer that problem by compressing capability into compact units. Instead of dedicating a fixed corner, shops roll the station where it’s needed.

This flexibility increases usage. When the tools come to the car, technicians are more likely to choose metal repair over filler. Over time, that changes shop culture. Metal work becomes normal again, not a specialty task.

Mobile setups also support on-site dealership work and fleet contracts. The ausbeulstation moves beyond the workshop walls without sacrificing quality.

Customers Notice the Difference, Even If They Can’t Explain It

Most customers don’t know repair terminology. They do notice when panels look factory-smooth under sunlight. They notice when paint matches perfectly because it was never disturbed. They notice when repairs don’t age poorly.

An ausbeulstation delivers those results quietly. No marketing tricks required. Word spreads the old-fashioned way, through cars that still look right years later.

That reputation compounds. Shops known for careful metal repair attract better jobs, better technicians, and better partnerships.

The Real Test of an Ausbeulstation Is Restraint

The most impressive ausbeulstation isn’t the one that handles every job. It’s the one that knows when not to intervene. Forcing metal repair where paint has already failed creates worse outcomes.

Good stations walk away from bad candidates. They explain the limits clearly. That honesty protects results and credibility. Customers respect it, even if they choose another route.

Restraint is a skill, just like pushing metal.

Conclusion

An ausbeulstation isn’t about chasing efficiency or trends. It’s about committing to repairs that respect the car’s original build and the owner’s long-term interests. Shops that treat it as a core discipline, not a side service, produce cleaner work, fewer complaints, and stronger reputations. The real advantage isn’t speed or cost. It’s the quiet confidence of metal that was fixed properly the first time.

FAQs

- How do I know if damage qualifies for repair through an ausbeulstation

Look for intact paint and dents without sharp creases. A quick inspection under reflection light usually tells the truth. - Does an ausbeulstation repair hold up over time

Yes, when the metal is properly reshaped and not overstressed, it ages like the original panel because it is the original panel. - Are aluminum panels suitable for ausbeulstation repairs

They are, but only with trained technicians. Aluminum behaves differently and punishes heavy-handed work. - Why do some shops avoid using their ausbeulstation

Lack of training, pressure to push volume, or habit. Filler is faster in the short term, riskier in the long run. - Is an ausbeulstation useful for luxury or classic cars

Absolutely. Preserving original paint and metal is often more important on high-value vehicles than on everyday cars.